Which industries are suitable for rocker arm winding machines? A single article to understand the structural advantages and application scenarios.

Date: 2025-07-10Id:291Views:

Are traditional rotary wrapping machines limited in their application? When dealing with heavy, tall, or unstable pallets, their efficiency often fails to meet expectations. In many packaging scenarios, the goods on pallets are large in volume, heavy in weight, and stacked high. Traditional rotary wrapping machines, which require the entire pallet to rotate, impose higher demands on the stability and load-bearing structure of the equipment. Once the goods are off-center, unstable, or the pallet structure is weak, problems such as poor rotation of the turntable, misalignment of the stack, and loose wrapping film may occur. Manual wrapping, on the other hand, is inefficient, inconsistent, and labor-intensive. To address these practical challenges, the swing arm wrapping machine, with its "goods remain stationary while the film wraps around them" design concept, has become the preferred equipment for heavy pallet packaging in an increasing number of enterprises.

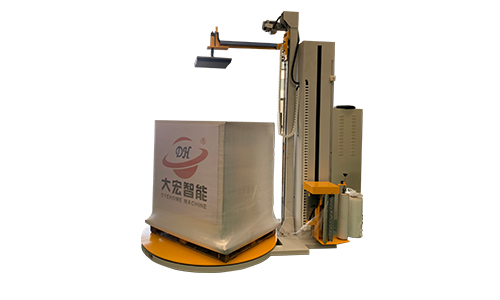

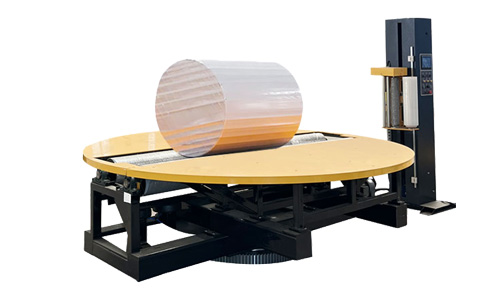

Swing arm structure, safer with stationary goods: An analysis of the structural advantages of swing arm wrapping machines

Swing arm wrapping machines use a cantilever rotation structure, where the goods remain stationary while the mechanical arm rotates around them to complete the wrapping. Compared to rotary machines, the swing arm structure has three significant advantages:

The goods do not rotate, making the packaging safer: Unstable centers of gravity, tall stacks, and large items will not sway or tip over due to centrifugal force.

Saves space and is flexible in adapting to the site: No large-diameter turntable is required, taking up less space and suitable for installation at the end of existing production lines.

Stable packaging tension and higher film utilization: Equipped with pre-stretching devices and variable frequency speed control systems, ensuring uniform film tension and tight wrapping.

These structural optimizations make swing arm machines superior to traditional wrapping machines in terms of packaging safety, efficiency, and equipment compatibility.

Widely applicable to various industries, specifically designed for challenging packaging scenarios

Due to its unique structural design, swing arm wrapping machines are particularly suitable for the following industries and types of goods:

Construction and building materials industry: Such as bricks, cement pallets, tiles, and stones, which are heavy, dusty, and difficult to package manually.

Home appliances: Large appliances like refrigerators, washing machines, and electric water heaters, which are prone to shaking, bumping, and loose packaging.

Chemical industry: Drummed liquids and bagged granular goods, with unstable centers of gravity, are prone to tipping over when using rotary machines.

Mechanical manufacturing industry: Irregularly shaped parts, large-sized palletized items, and heavy metal components, which require complex and robust packaging.

Export enterprises: For customers requiring long-distance transportation, moisture-proof, and anti-scattering pallet packaging, swing arm wrapping is more standardized and secure.

In addition, swing arm wrapping machines can also be integrated with conveyor lines for automatic sensing, automatic wrapping, and automatic film cutting operations, making them an important component of intelligent packaging systems.

Customer case: A brick factory in Jiangsu saw a more than 100% increase in packaging efficiency after introducing a swing arm machine

Take a large brick manufacturing enterprise in Jiangsu as an example. They need to ship 300 to 500 pallets of bricks every day. Previously, they used manual wrapping, which was inefficient and resulted in loose packaging and easy stack disintegration during transportation. After introducing a swing arm wrapping machine, the packaging time per pallet dropped from 23 minutes to just over one minute. The packaging became standardized and neat, and transportation became safer. At the same time, they saved on human resources, and the overall packaging efficiency increased by more than 100%, becoming a crucial guarantee for stable delivery in the "last link" of their production line.

If you encounter any of these problems, a swing arm wrapping machine is worth considering

If your factory has any of the following situations - heavy, tall, off-center, unstable, easily shaken, or easily scattered pallets - a swing arm wrapping machine is definitely more suitable than traditional rotary wrapping machines. It not only has a high degree of automation, is easy to maintain, but can also be equipped with modules such as top film covering, strapping, barcode printing, and data upload, making it a key component of an intelligent shipping packaging system. In the future, the requirements for packaging efficiency, packaging stability, and shipping standardization will only increase. Choosing the right wrapping machine for your industry is the true starting point for optimizing the packaging process.

Related