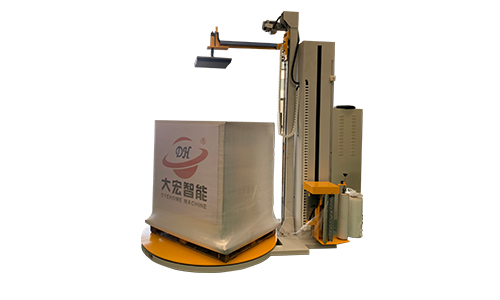

Rotary Arm Stretch Wrapping Machine: A Stationary Wrapping Solution for High or Unstable Pallets

Higher stability requirements during wrapping for high-load pallets

In real packaging operations, some palletized loads are tall, have a high center of gravity, or lack sufficient overall stability. When using turntable-type wrapping machines, pallets may sway during rotation, which can affect film adhesion and even compromise the load structure. For such conditions, the rotary arm stretch wrapping machine provides a more suitable solution by keeping the load stationary while the wrapping mechanism moves.

Rotary arm structure enables stationary load wrapping

The core feature of the rotary arm stretch wrapping machine is that the wrapping unit rotates around the pallet while the load itself remains stationary. During operation, the rotary arm guides the stretch film around the pallet, while the film carriage moves vertically along the mast to complete continuous wrapping from bottom to top. This structure avoids inertia-related instability caused by pallet rotation and ensures a smoother wrapping process, making it particularly suitable for pallets that should not be rotated.

Pre-stretch film carriage balances film adhesion and material control

The machine is typically equipped with a pre-stretch film carriage that stretches the film before wrapping, ensuring stable tension while conforming closely to the load surface. Operators can adjust the number of wrapping cycles and the pre-stretch ratio according to pallet height and load weight, allowing the wrapping process to better match actual packaging requirements. This configuration helps maintain wrapping quality while managing film usage effectively across different applications.

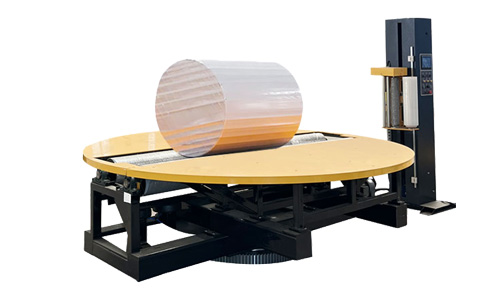

Compatible with various pallet types and highly adaptable to different scenarios

The rotary arm stretch wrapping machine is suitable for carton pallets, bagged goods, grouped drums, and mixed-load pallets. For tall, unevenly weighted, or non-rotatable pallets, the machine completes outer wrapping without changing the stacking method.

In industries such as chemicals, building materials, food, beverages, and warehousing logistics, this equipment is commonly used in outbound packaging processes where high stability is required.

Flexible standalone or inline operation for easy layout

The rotary arm stretch wrapping machine can be used as a standalone unit or integrated with conveyor systems depending on site conditions. For continuous packaging stations where loads must remain stationary, the rotary arm design helps reduce manual intervention and ensures smoother packaging flow.

The machine features a clear operating logic and is easy to adjust and maintain across different working environments.

Practical value in packaging processes

By keeping the pallet stationary throughout the wrapping cycle, the rotary arm system minimizes instability caused by rotation. Consistent wrapping paths and adjustable parameters help ensure uniform outer packaging for each pallet, facilitating subsequent warehousing, stacking, and transportation.

A more reliable wrapping solution for non-rotatable pallets

With its stationary load and rotating arm design, the rotary arm stretch wrapping machine provides a more suitable and stable wrapping method for high or unstable pallets.