Rotary Arm Online Top Sheet Stretch Wrapper Enables Integrated Pallet Wrapping for Continuous Outbound Operations

Date: 2026-02-06Id:525Views:

Integrated Online Packaging Equipment for Side Wrapping and Top Covering

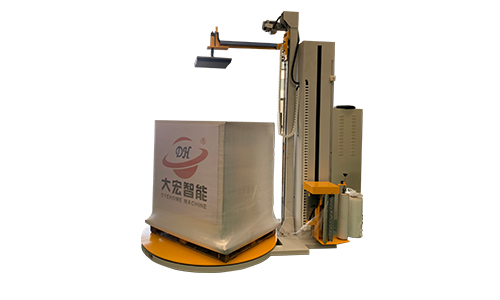

In highly automated production and warehousing environments, pallet loads must be packaged during conveying to maintain efficiency and consistency. The rotary arm online top sheet stretch wrapper addresses this need by integrating rotary arm wrapping with top sheet covering, allowing pallets to complete side wrapping and top protection simultaneously on the conveyor line, reducing manual involvement and improving packaging rhythm.

Rotary Arm Wrapping Structure for Stable Online Operation

The machine adopts a working mode where the pallet remains stationary on the conveyor while the rotary arm rotates around it. Compared with turntable structures, this design is better suited for conveyor integration, avoiding inertial effects caused by pallet rotation. It is particularly suitable for tall or unstable pallet loads, ensuring stable wrapping during operation.

Top Sheet Covering Enhances Overall Load Protection

While completing side wrapping, the machine applies a top sheet film to the pallet load, significantly improving dust and moisture resistance. The combination of side wrapping and top covering forms a fully enclosed packaging structure, offering enhanced protection during storage, transportation, and outdoor handling.

Automated Interlocked Control Supports Continuous Outbound Flow

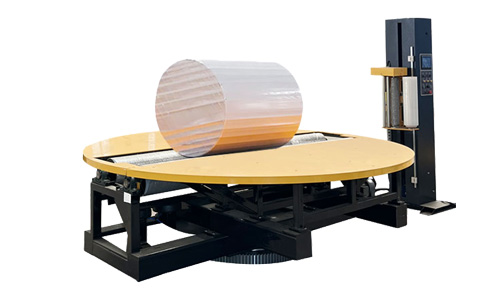

The rotary arm online top sheet stretch wrapper can be linked with roller conveyors and chain conveyors through signal interlocking. It supports automatic pallet entry, positioning, wrapping, top covering, and exit in a continuous process. Wrapping turns, covering position, and operating speed can be adjusted according to pallet specifications, ensuring stable operation under varying outbound rhythms.

Stretch Film Wrapping Balances Load Stability and Material Consumption

Using stretch film with controlled tension, the machine secures pallet loads while optimizing film usage. Adjustable wrapping parameters ensure uniform film distribution, helping reduce material waste and maintain consistent packaging quality, making it suitable for long-term, high-frequency operation.

Mature Structure for Long-Term Online Operation

The machine is designed for continuous-duty applications, with stable key components and smooth operation. Its optimized structure and control logic help minimize mechanical wear caused by frequent start-stop cycles, providing a reliable wrapping and top covering solution for automated packaging lines.

Customer Focus: Enhanced Packaging Integrity and Outbound Efficiency

For end users, the main value of the rotary arm online top sheet stretch wrapper lies in achieving both pallet stabilization and top protection without increasing labor input. By integrating wrapping and covering functions into a single machine, outbound processes become more efficient, packaging quality more consistent, and overall logistics performance significantly improved.

Related