Is it difficult to pack high-stack heavy goods? The rocker-type film wrapping machine makes wrapping packaging more stable and faster

Date: 2025-07-18Id:302Views:

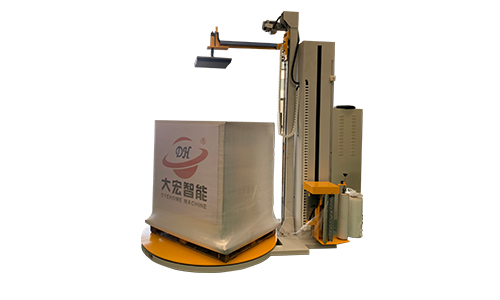

In the chemical, building materials, paper, food, glass and other industries, the goods transported by pallets often have the following characteristics: high stacks, biased center of gravity, heavy pallets, irregular and easy to tilt. Although the traditional turntable wrapping method is common, it is easy to "not adapt to the local conditions" in these scenarios: the goods shake severely when rotating, the film is not tightly wrapped, and the stack is easy to loosen during shipment, which affects the customer's receiving experience and may also cause complaints or cargo damage. The rocker-type film wrapping machine, also called the cantilever wrapping machine, is a structural device designed to solve these problems. It is a "film wrapped around the goods without moving the goods" structure, which can truly make packaging more stable, faster and safer.

The structure is upgraded, the goods do not rotate during the packaging process, and the wrapping is tighter and safer

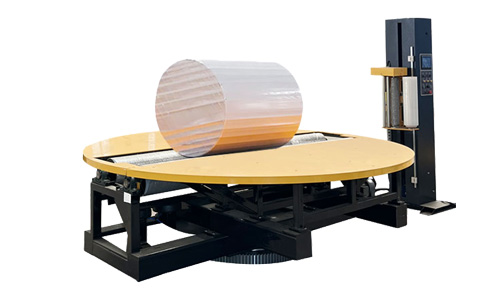

The biggest feature of the rocker-type film wrapping machine is that the goods are fixed and the film wrapping arm rotates around the goods at high speed for wrapping and packaging. This structure is particularly suitable for pallet goods that are not suitable for rotation due to excessive weight, special shape or unstable stacking.

The rocker-type film wrapping machine has the following advantages: adjustable pre-stretching film frame, saving film materials and ensuring tight wrapping; equipped with an automatic film breaking device, which automatically breaks and strokes the film after packaging without manual intervention; the rocker system has automatic reset + emergency brake function to ensure safe operation; the packaging height can reach 2000mm, supporting high cargo stacking operations; the conveyor line can be customized with rollers, chains and other forms to adapt to the continuous operation scene of the assembly line.

Truly realize unmanned packaging: automatic identification of goods + one-click operation

Unlike traditional manual film wrapping machines, the rocker film wrapping machine has been fully upgraded to an intelligent sensing + automatic control system. After the goods enter the operation area through the conveyor line, the equipment can automatically detect the size and position of the goods, and complete: automatically start the film wrapping program; automatically lift the film rack; automatically break the film and caress the film; automatically convey the packaging to the waiting position after completion.

The whole process does not require manual intervention, the packaging rhythm is stable, and it supports 20~40 pallets/hour continuous operation, which is suitable for supporting the use of automated production lines and centralized packaging areas. For companies with tight labor or fast delivery rhythm, it is the preferred solution to replace manual packaging.

Adapt to the outbound delivery of goods in multiple industries, support personalized customization and system integration

The rocker film wrapping machine supports non-standard customization, and can be equipped with a top pressure device to meet the stability of light cargo packaging. It can also be expanded to connect with automatic weighing, code scanning system, strapping equipment, and ERP system linkage to create a complete shipping packaging station.

Widely used in the following industries: Chemical raw materials industry: barreled, ton bags, bagged goods wrapping and reinforcement; building materials industry: bricks, tiles, mortar heavy pallet packaging; home appliance industry: dust-proof film wrapping before transportation of large equipment; paper industry/textile: integrated packaging of high-stack products such as paper rolls and cloth rolls.

Packaging requires speed and stability, and the rocker arm machine is the "standard configuration" for heavy cargo packaging

As companies' requirements for delivery efficiency, packaging standardization, and personnel configuration optimization are increasing, traditional manual film wrapping and turntable equipment are no longer able to meet the shipping needs of heavy, high-stack, and complex-structured pallets. The rocker arm film wrapping machine has become the "main packaging equipment" of more and more manufacturing companies with its design concept of rotating equipment around the goods, stable packaging structure, and highly automated process control. For factories that need to speed up and improve quality and save manpower, this equipment is not only an improvement at the end of production, but also a guarantee of delivery efficiency.

Related