How to Automatically Wrap Pallets in Continuous Outbound Lines? Rotary Arm Online Stretch Wrapping Machine Integrated with Conveyor Systems

Date: 2026-01-27Id:509Views:

Requirements for Pallet Wrapping in Continuous Outbound Operations

In automated production and warehouse outbound environments, pallets typically move continuously along conveyor lines, requiring packaging equipment to match the operational cycle. For tall or stability-sensitive pallets, turntable rotation can affect conveyor interfacing and operational stability, creating the need for alternative wrapping structures.

Working Principle of the Rotary Arm Online Structure

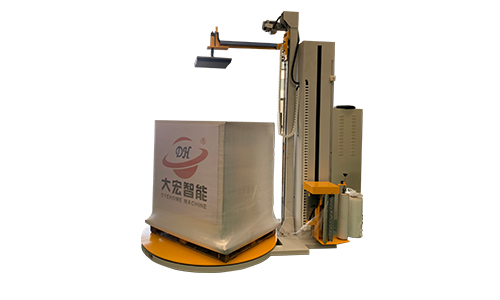

The rotary arm online stretch wrapping machine allows pallets to enter the wrapping station via the conveyor while remaining stationary. The rotating arm drives the film carriage to wrap around the load. During wrapping, the machine remains synchronized with upstream and downstream conveyor systems, making it suitable for continuous pallet flow and enabling automatic positioning, wrapping, and release.

Integration of the Online Wrapping Process

In operation, pallets are conveyed into the wrapping zone, where positioning is completed and safety devices are activated. The rotary arm then performs the wrapping sequence according to preset programs. After wrapping is completed, the arm returns to its home position, and the conveyor resumes operation, transferring the pallet to the next station. The entire process requires no manual intervention, ensuring continuous outbound rhythm.

Control of Wrapping Parameters and Packaging Consistency

The rotary arm online stretch wrapping machine allows programmable control of wrapping cycles, film carriage speed, and reinforcement positions. This ensures consistent wrapping results for every pallet. Stable tension control and repeatable motion paths reduce inconsistencies caused by manual operation, making the system suitable for standardized, high-volume outbound packaging.

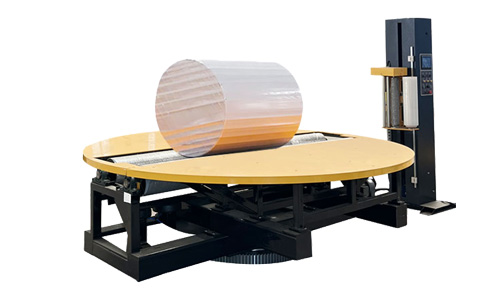

Differences Compared with Turntable Online Wrapping Machines

Compared with turntable-style online wrappers, the rotary arm structure does not require pallet rotation, making it more suitable for long conveyor lines or heavy-duty pallet systems. In applications with high pallet stability requirements, rotary arm machines can achieve automatic wrapping without altering the existing conveyor layout.

Applicable Industries and Installation Locations

The rotary arm online stretch wrapping machine is widely used in industries such as chemicals, building materials, food and beverages, and new energy. It is commonly installed at the end of production lines or centralized outbound areas and can be customized to integrate with pallet conveyors and palletizing systems, providing stable support for automated packaging workflows.

Related