High-stacked goods packaging problem? This rocker wrapping machine provides an intelligent solution

Date: 2025-04-27Id:171Views:

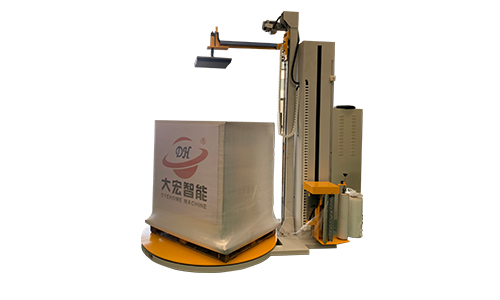

In modern industrial production, the packaging of high-stacked and irregularly shaped goods has always been a problem that plagues enterprises. The traditional wrapping packaging method is not only inefficient, but also labor-intensive for operators. In addition, the packaging is not firm, which often leads to the collapse and damage of goods. In response to this industry pain point, the LR1800FZ cantilever wrapping machine innovatively developed by Shandong Dahong Intelligent Equipment Co., Ltd., with its unique working principle and intelligent design, is providing efficient and reliable packaging solutions for many industries such as food and beverage, chemical building materials, and electronic appliances.

1. Subverting the traditional intelligent packaging method

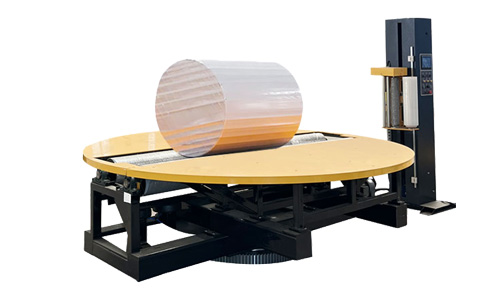

Unlike conventional pallet wrapping machines, Dahong LR1800FZ adopts an innovative cantilever rotation design. The equipment wraps around stationary goods for packaging, which perfectly solves the industry problem that high-stacked goods (up to 2000mm) are prone to collapse during rotation. This "goods are not moving, equipment is moving" working mode has multiple advantages:

The packaging stability is significantly improved: it avoids the inertia effect caused by the rotation of goods in the traditional way, and is particularly suitable for fragile and easy-to-fall high-stacked goods.

Higher space utilization: The equipment occupies a smaller area and is suitable for factory layouts with limited space.

Safer operation: Personnel do not need to approach the rotating area, greatly reducing the risk of work-related injuries.

The equipment is equipped with an advanced automatic sensing system that can accurately identify the height and shape of the goods, automatically adjust the number of winding layers, film tension and other parameters, and the packaging efficiency can reach 20-40 pallets/hour, which is 3-5 times that of manual packaging.

The packaging supervisor of a well-known building materials company gave feedback: "Our 2-meter-high tile pile used to take 10 minutes per pallet to be manually packed. Now it can be completed in 3 minutes with this equipment, and the packaging is more solid, and the transportation damage rate has been reduced by 90%."

2. Six core technical advantages

1. High-pile packaging stabilization system

Reinforced cantilever structure, with a maximum load-bearing capacity of 2000kg

Optional hydraulic top pressure device to prevent high-rise cargo from tipping over

High-sensitivity emergency brake system (response time <0.5 seconds)

Automatic cantilever reset function to ensure that the starting position of each package is consistent

2. Intelligent film control technology

Pre-stretching The film rack can achieve a 250% stretch rate, saving 30% of the film usage

The independently developed film hot stamping mechanism realizes "tailless film" packaging, which is beautiful and neat

The film feeding speed is 6-18rpm steplessly adjustable to meet the needs of different goods

Film breaking accuracy ±2mm to avoid film waste

3. Fully automated assembly line integration

The equipment can be seamlessly connected with various conveyor lines to achieve:

Automatically identify the arrival of goods

Automatically start and stop the packaging program

True unattended operation, saving labor costs

With the in-depth promotion of intelligent manufacturing and Industry 4.0, the automation and intelligence of packaging equipment has become an irreversible trend. Dahong Intelligent LR1800FZ cantilever wrapping machine is helping more and more companies to achieve intelligent upgrades in the packaging process with its innovative design concept and excellent performance.

In the future, with the integrated application of technologies such as the Internet of Things and big data, this type of intelligent packaging equipment will also achieve a higher level of automation and informatization, providing stronger support for the digital transformation of the manufacturing industry. For companies that are seeking breakthroughs in packaging efficiency, choosing a suitable intelligent packaging solution will be a key step to gain an advantage in the fierce market competition.

If you need more product information, watch actual machine demonstrations or obtain industry solutions, please contact Dahong Intelligent's local service team or visit the company's official website. Our professional engineers will provide you with customized intelligent packaging solutions to help companies improve packaging efficiency and reduce operating costs.

Related