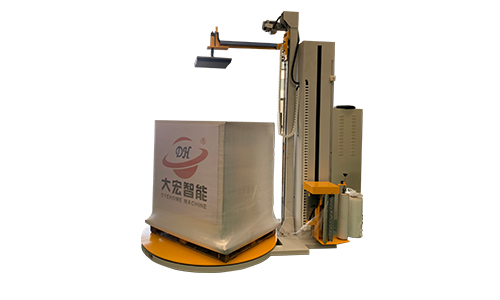

High-speed rocker arm wrapping machine improves factory delivery efficiency and is suitable for automatic packaging of pallets of various specifications

Date: 2025-06-11Id:245Views:

How to adapt high-speed rocker arm wrapping machine to pallets of various specifications to achieve stable and efficient packaging

With the acceleration of modern logistics delivery rhythm, traditional manual film wrapping methods can no longer meet the dual requirements of enterprises for efficiency and packaging consistency, especially in the face of industry scenarios with a variety of pallet types and high delivery frequency. With its structural advantages and film output efficiency, the high-speed rocker arm wrapping machine not only solves the bottleneck of manual film wrapping, but also provides a more reliable automated wrapping solution for manufacturing, warehousing, e-commerce and other fields. This article will systematically analyze how the high-speed rocker arm wrapping machine can improve the packaging capacity at the end of the production line from three dimensions: equipment principle, structural characteristics, and typical application cases, and bring tangible efficiency benefits to enterprises.

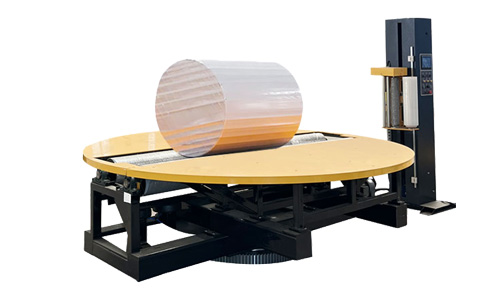

Automatic wrapping solutions for special-shaped pallets and large materials

The high-speed rocker arm wrapping machine is different from the traditional turntable structure. Its core advantage is that the rocker arm does not rotate when the goods are not moving, which makes it more stable when facing large-sized or unstable-center-of-gravity goods. Its rocker arm system uses frequency conversion control to achieve high-speed operation in the range of 6~18rpm. It is equipped with the tension control system of the film frame and the synchronous lifting technology of the upper and lower parts to ensure that the film is evenly covered and tight, and it is not easy to fall off. At the same time, the film roll tensioning process is completed automatically without manual intervention. For those goods with irregular structures or large differences in pallet sizes, such as large panels and high cabinet products commonly seen in the building materials, furniture, and electrical appliance industries, the equipment can automatically adjust the number of film wrapping circles and the wrapping area according to the preset program to improve the compatibility of the packaging.

Practical configuration determines the stable operation and service life of the equipment

An excellent high-speed rocker arm wrapping machine does not rely solely on speed to win, but the configuration of the whole machine is also crucial. At present, most mainstream equipment in the industry adopts PLC+touch screen control system, which supports multiple sets of winding parameter presets and one-button call, so that operators can quickly switch packaging modes according to different shipment batches. In addition, the equipment is equipped with a photoelectric automatic sensing system, which can intelligently identify the height of the goods and realize all-round winding; the film frame uses a pre-stretching mechanism to effectively save the amount of film materials and reduce packaging costs while ensuring the tight winding effect. The main structure of the equipment adopts steel spraying technology, which is rust-proof and wear-resistant, and can adapt to long-term operation in complex environments such as high dust and high humidity, ensuring long-term stable operation of the equipment.

Actual application scenarios of warehousing and logistics companies: significant efficiency improvement

Taking a logistics cloud warehouse with an annual shipment volume of more than 200,000 pallets as an example, it originally relied on 7-10 people to rotate for manual film wrapping, which was not only unstable in efficiency, but also seriously wasted film materials. Since the introduction of two high-speed rocker arm wrapping machines, the number of team members has been reduced to 1 person for inspection, and the hourly shipment capacity has been increased to more than 40 pallets. The equipment has high stability, and there is basically no film jamming or film breaking problems. Since the equipment supports automatic film breaking and pasting functions, employees do not need to frequently replace film rolls on pallets, which effectively reduces operational risks. After one year of operation, the company has achieved remarkable results in saving labor costs and improving the smoothness of shipments. Customer feedback shows that the equipment investment payback period is less than 8 months, and the cost performance is much higher than other general-purpose wrapping equipment.

High-speed rocker arm wrapping machine helps companies build efficient shipping packaging lines

The current manufacturing and warehousing industries have an increasingly urgent demand for automation and cost-saving and efficiency-enhancing in the packaging process, and the high-speed rocker arm wrapping machine is an efficient tool to solve the "multi-specification, multi-batch, multi-task" packaging scenario. Through highly automated operation, stable mechanical structure and wide applicability, the equipment not only improves the overall efficiency of terminal shipments, but also provides strong support for packaging standardization and replicability for enterprises in the fierce market competition. If you are facing problems such as shortage of manual film wrapping, inability to keep up with the shipment rhythm, and unstable packaging, you may wish to learn more about the high-speed rocker arm wrapping machine solution. I believe it will play an irreplaceable role in your shipment process.

Related