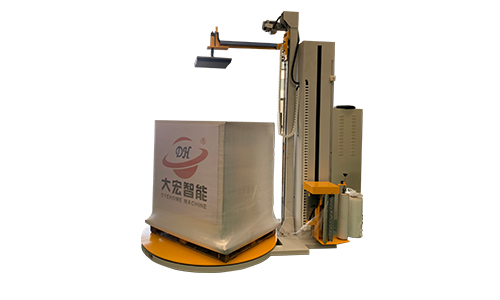

Fully Automatic Rotary-Arm Pallet Wrapping Machine: An Automated Packaging Solution for Tall Loads and Unstable Pallets

Date: 2025-12-12Id:456Views:

Higher demands for stability when packaging tall loads and unstable pallet structures

In industries such as food and beverages, chemicals, paper products, electronics, and building materials, pallet stacking often features tall heights, loose combinations, and shifting centers of gravity. Traditional turntable wrappers may cause load wobbling when handling these pallets, while manual wrapping is inconsistent and labor-intensive. As production speeds accelerate, companies increasingly require higher packaging stability, faster throughput, and greater automation.

The fully automatic rotary-arm pallet wrapper ensures the load remains stationary while the arm rotates around it, keeping the pallet stable throughout the wrapping cycle. This design provides a reliable solution for tall loads and irregular pallets.

Equipment Structure: Rotary arm and pre-stretch film carriage enable continuous automated wrapping

The rotary arm is the core of the system, operating at a variable speed of 6–18 rpm with smooth frequency-controlled adjustment. The arm automatically returns to its home position after each cycle and features an emergency braking mechanism for safe operation.

The film carriage adopts a powered pre-stretch system with up to 250% stretch ratio, ensuring consistent film tension and reduced material usage. A chain-driven mast controls the vertical movement of the film carriage, adjustable via frequency inverter, supporting wrapping heights from 800–2000 mm and ensuring full coverage regardless of load height.

The automatic film clamp-and-cut unit completes gripping, cutting, and sealing of the film, enabling truly unmanned operation. The PLC control system automatically detects pallet height and adjusts wrapping cycles, layer counts, and reinforcement patterns, ensuring repeatable and reliable packaging.

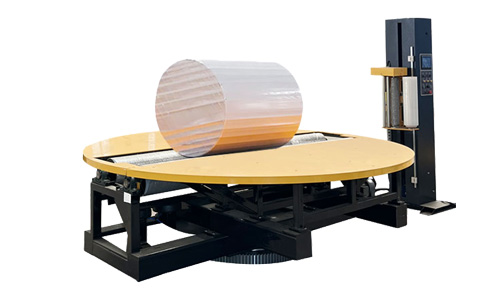

Packaging Advantages: Stationary load ensures superior stability for tall and lightweight pallets

The key advantage of a rotary-arm wrapper is that the pallet does not rotate. This is crucial for tall loads, loose carton stacks, and heavier pallets. The rotating arm wraps the load while the goods remain stable, preventing inertia-related shaking.

The machine supports bottom reinforcement, top reinforcement, and spiral wrapping, forming a tightly bonded protective membrane. In practical applications, film overlap and uniformity are more consistent, making it suitable for products demanding high aesthetic standards and transport stability.

The automatic film-breaking device also improves film tail handling, reducing issues such as film lift or peeling during transport and enhancing overall packaging quality.

Industry Applications: Adaptable for standalone or fully automated conveyor-line operations

The fully automatic rotary-arm pallet wrapper can operate independently or integrate with roller conveyors, chain conveyors, or palletizing systems to create a fully automated packaging line. It is ideal for:

Food & beverages: unstable carton or bottle pallets

Chemicals & paper: drums, bags, and tall heavy loads

Building materials: bricks, tiles, boards requiring strong side binding

Electronics: high standardization requirements, film appearance affects final delivery quality

Logistics & warehousing: improves outbound processing speed when embedded in automated lines

Optional features include top platen, extended arm height, and reinforced structure, meeting various packaging requirements.

Stable wrapping for tall and high-center-of-gravity loads

Through its rotary-arm system, pre-stretch film carriage, automatic film handling, and PLC control, the fully automatic rotary-arm pallet wrapper provides efficient, automated, and stable wrapping.

Its “stationary load, rotating arm” design delivers exceptional performance for tall loads, lightweight pallets, and irregular stacking. For factories seeking improved stability, outbound efficiency, and automation, this machine offers long-term value and reliability.

Related