Frequent luggage bumps? Airport luggage wrapping machine enhances outer-case protection

Date: 2025-12-01Id:445Views:

Checked luggage easily bumped? Luggage wrapping devices improve outer-case protection

With continuously growing passenger flow, checked luggage undergoes repeated transfers during sorting, security, conveyor transport and loading/unloading. Suitcases are vulnerable to scratches, surface dents and collisions—especially soft-sided, older or non-hardcase luggage. Luggage wrapping machines form a continuous protective film layer that gives luggage a more stable external protection, helping to reduce damage in high-frequency handling scenarios and saving travelers unnecessary trouble.

Wrap-around film delivers full-coverage protection during transport

Airport luggage wrapping equipment typically drives rotation via a turntable while the film carriage performs synchronized wrapping. During spiral wrapping, the film evenly covers the suitcase surface to form a continuous protective layer. The film’s tensile strength reduces direct contact between luggage and hard surfaces such as conveyors and pallet edges, lowering abrasion, scratches and dent risks. Additionally, the film provides basic moisture resistance during brief rain or snow exposure, keeping luggage cleaner when moved between outdoors and indoor areas.

Reduces risk of openings—improves enclosure security during transport

Passengers often worry that suitcase seams or zippers may open from vibration during transit, causing contents to spill or zippers to fail. The wrap creates a certain binding effect on the case exterior, stabilizing closure points and reducing accidental opening. For items secured only by external straps, weak tape or temporary fasteners, film wrapping further enhances overall integrity—offering greater peace of mind for business travelers, passengers with multiple transfers or long transit times.

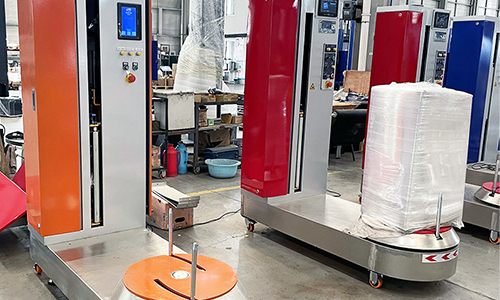

Turntable structure adapts to multiple luggage sizes and raises airport throughput

Luggage wrapping machines are commonly semi-automatic or automatic; staff place the suitcase on the turntable and adjust the column position to the luggage size, then the machine wraps. With controlled, uniform rotation, different shapes and sizes all receive stable coverage. For airports with large daily luggage volumes and peak demands, machine reliability and operational rhythm are critical. A single piece of luggage can typically be wrapped in a matter of seconds, greatly improving frontline service speed and reducing passenger queuing.

Optional module expansion fits airport operations

To meet diverse airport needs, luggage wrapping machines can be equipped with optional features such as weighing scales, cameras, displays and foot pedals. Weighing allows passengers to quickly confirm baggage weight before wrapping, reducing rework due to overweight items. Camera systems can record wrapping status for traceability. Foot pedals enable high-frequency operators to start quickly, improving on-site throughput. These options make machines better aligned with airport and large hub workflows while providing passengers a more convenient checked-luggage service.

Airport luggage wrapping machines use mechanical full-surface wrapping to strengthen outer protection of luggage, minimizing surface wear, collisions and accidental openings during checked transport. With fast operation, adjustable structure and optional modules, these machines suit high-flow airports, train stations and transport hubs—making them an important equipment choice for passenger baggage service areas.

Related