Efficient and Safe Packaging Solutions for High-Center-of-Gravity Pallets with Swing Wrappers

Date: 2025-08-14Id:341Views:

Meeting the Packaging Needs of High-Center-of-Gravity and Irregular-Shaped Cargo

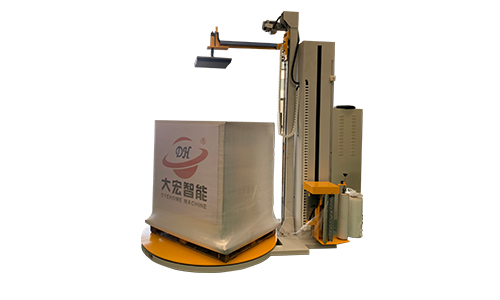

In palletized transportation in industries such as chemicals, food and beverages, building materials, and electronics, cargo often encounters high height, a high center of gravity, or irregular shapes. Traditional turntable wrapping methods can easily cause cargo to tilt or even slip due to centrifugal force. Swing wrappers, which wrap cargo while the film frame moves, ensure packaging security while improving speed and safety. They are particularly suitable for the efficient packaging of medium-to-large cargo and products prone to tilting. Equipment Principle and Core Features

The core structure of the swing arm wrapping machine is a swing arm that drives the film frame to rotate around the palletized cargo, while simultaneously raising and lowering the film frame to achieve full film coverage. The machine utilizes a PLC programmable control system and a touchscreen interface, allowing users to configure parameters such as the number of wraps, reinforcement locations, and wrap angle height according to their needs. The film frame pre-stretch ratio is adjustable from 150% to 300%, helping to control film consumption and improve wrapping density. The swing arm speed and film frame raising and lowering speed can be set independently to ensure uniform tension at different locations. Some models also feature optional automatic film feeding, film cutting, and film caressing mechanisms, as well as a top-pressing device and a top-film covering function, enabling multifunctional, integrated packaging.

Applicable Industries and Application Value

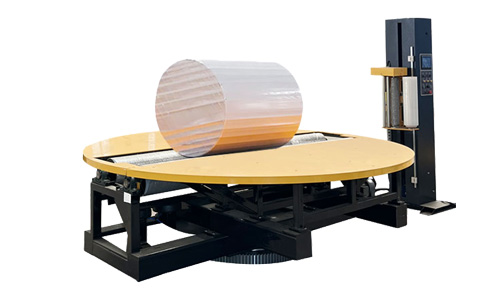

The swing arm wrapping machine is widely used in industries such as chemical raw materials, glass products, paper products, home appliances, and bulk building materials. It is particularly suitable for heavy, high-stacked, or irregularly shaped palletized cargo. Compared to turntable-type wrapping machines, the swing-arm structure eliminates the risk of high-center-of-gravity cargo shifting during high-speed rotation. It also supports integration with conveyor lines, balers, and capping machines, enabling fully automated packaging operations and improving overall production line efficiency.

Case Study: Safe and Efficient Packaging Solutions for the Building Materials Industry

A large building materials company needed to wrap pallets up to 1.8 meters high during shipment. Manual or turntable wrapping methods easily caused the pallets to wobble during rotation. The introduction of a fully automatic swing-arm wrapping machine reduced the packaging time per pallet to under 60 seconds. The system significantly improved transportation stability by providing three reinforcement turns at the bottom, two reinforcement points in the middle, and an increased number of top reinforcement turns. The machine seamlessly integrates with the company's roller conveyor line, enabling unmanned, continuous operation and reducing manual labor and packaging inconsistencies.

Conclusion and Selection Recommendations

When selecting a swing-arm wrapping machine, companies should prioritize factors such as cargo height, center of gravity, weight, and transport distance. They should also consider the machine's film frame stretching method, swing-arm speed range, automation features, and safety protection level. Reasonable selection can not only improve packaging efficiency and stability, but also reduce consumables and labor costs in long-term use, and enhance the overall logistics competitiveness of the enterprise.

Related