Cantilever Wrapping Machines for High-Frequency Shipments: Solving Packaging Bottlenecks

Date: 2025-09-03Id:368Views:

Limitations of Fixed Turntable Equipment

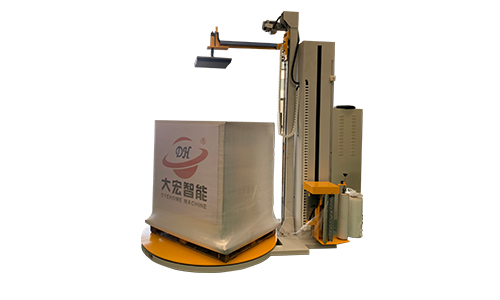

With the increasing popularity of palletized shipments, wrapping equipment has become a near-essential workshop necessity. However, for large, heavy, or irregularly shaped cargo, conventional turntable equipment requires the pallet to rotate with the turntable during the packaging process, which not only imposes operational limitations but can also compromise cargo stability. To meet the needs of these specialized scenarios, the cantilever wrapping machine has emerged. Its "stationary cargo, rotating arm" design eliminates the risks associated with heavy or tall cargo rotating, making it ideal for companies with high volumes and high shipping frequencies. Equipment Features: High Speed, Stability, and Intelligence

The cantilever wrapping machine's greatest advantage lies in its high speed and stability. The rotating arm wraps the pallet around the cargo, while the pallet remains stationary. This ensures safety while also accommodating heavy and high-profile cargo.

The machine is typically equipped with a pre-stretched film holder, achieving a film stretch ratio of over 250%, ensuring secure film retention while reducing film consumption. The arm's speed supports variable frequency control, allowing it to wrap up to 40 pallets per hour, significantly improving packaging efficiency compared to traditional equipment. The intelligent control system automatically detects cargo height, allowing users to customize the number of wraps and top or bottom wrap reinforcements to achieve a customized packaging solution. It also supports automatic film cutting and can be directly linked to a conveyor line, creating a fully automated, unmanned packaging line.

Application Industries: Suitable for high-volume shipments and specialized cargo.

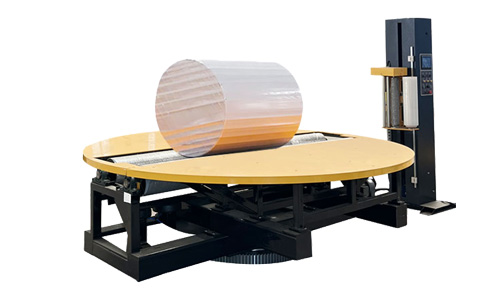

Cantilever wrapping machines are widely used in industries such as food and beverage, chemicals, papermaking, building materials, and electronics. In the food and beverage industry, it can quickly complete packaging for high-frequency pallet shipments, ensuring neat and aesthetically pleasing packaging. In the chemical industry, heavy goods such as ton bags and barrels can be securely reinforced using cantilever equipment. In the paper and non-woven fabric industries, large-diameter coils can be wrapped without rotating, reducing waste. In the building materials industry, cantilever packaging for goods such as tiles and panels provides greater security and stability. In the export logistics industry, this equipment enables fully automated packaging, improving packaging consistency and transport reliability.

Case Study: Packaging Upgrade for a Building Materials Company

A building materials manufacturer previously used a traditional turntable wrapping machine, but its efficiency and safety were insufficient for high-frequency shipments and large pallets. After introducing a cantilever wrapping machine, their packaging efficiency increased to over 40 pallets per hour, reducing manual operations by 40%. The machine's pre-stretching function reduced film usage by approximately 15%, effectively controlling overall costs. More importantly, the packaged goods exhibited significantly enhanced stability during transportation, with customer-reported breakage rates significantly reduced. The company's head stated that the investment in this equipment not only improved shipping efficiency but also earned them greater customer recognition in order delivery. A New Choice for Efficiency and Safety

The cantilever wrapping machine, with its unique advantage of "stationary cargo, rotating equipment," successfully solves the packaging challenges of heavy and tall cargo. It not only improves packaging efficiency, but also balances safety and consumables savings, providing strong support for businesses in a highly competitive market. In the future, with the advancement of automation and intelligentization, cantilever equipment will gradually become standard equipment in workshops across more industries, helping companies achieve efficient, safe, and standardized packaging upgrades.

Related