Why do more and more shipping factories list automatic sword-piercing balers as "standard" for packaging lines?

Date: 2025-05-27Id:218Views:

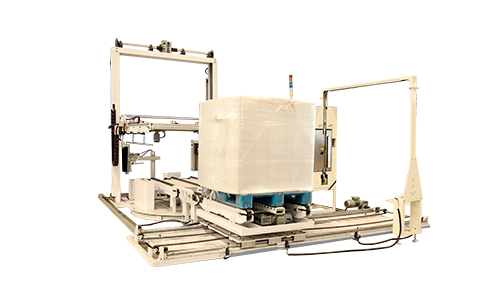

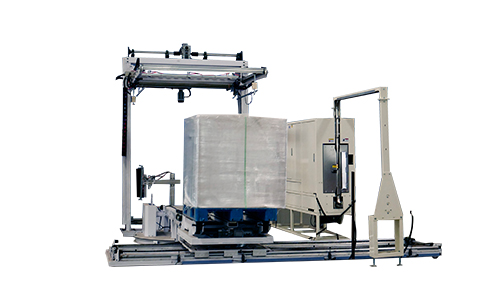

The automatic sword-threading baler is a high-performance packaging equipment designed for palletized goods. It automatically delivers straps at the bottom of the pallet through the "sword-threading" structure to complete the whole process of bundling, tightening, hot melting and cutting. The equipment can be integrated with the palletizing line, winding packaging line and conveying system, or it can be used alone in the whole pallet shipping area. It is widely used in daily necessities, food and beverage, building materials, chemicals, electrical appliances, e-commerce warehousing and other industries, and is an indispensable part of building an automated packaging process.

Take a large home furnishing company in Zhejiang as an example. The company needs to ship thousands of pallets of furniture parts every day. The goods are of different shapes and stacked high, and the transportation stability requirements are extremely high. The original manual strapping and packaging is not only inefficient and labor-intensive, but also frequently has problems such as inadequate strapping and loose straps. After the enterprise upgrades and deploys the automatic sword-piercing baler, the whole pallet of goods only needs to stay in the equipment strapping area. The system automatically identifies the position of the pallet, and the sword-piercing device quickly feeds the tape to the bottom of the pallet and completes the whole strapping process. The average strapping time per pallet is only 20 seconds, which greatly improves the delivery efficiency and packaging tightening standards.

In terms of operation, the equipment adopts modular PLC program control, supports setting the number of strapping circles, strapping position, tension parameters, strapping speed and other data, can save multiple sets of packaging programs, and realize fast switching of multiple batches of products. After the strapping is completed, the tape is automatically broken and bonded, the tail of the tape is neat, the strapping is firm, and no excess tape or joint fragments are left. The whole machine is equipped with abnormal alarm prompts, emergency stop protection, safety photoelectric detection and other functions to ensure safe operation and continuous operation.

In terms of usage scenarios, the automatic sword-piercing baler can be deployed as a single-machine strapping station, or it can be linked to form a packaging line "palletizing-threading-film wrapping-labeling"* for automated shipment and packaging. The equipment is compatible with a wide range of pallet sizes, has adjustable stacking height, and can adjust the strapping position as needed. It is particularly suitable for modern production workshops and storage bases with high-frequency shipments, tight labor, or high requirements for strapping standards.

Compared with manual strapping, each automatic sword strapping machine can save an average of 2 people's operating intensity, and the efficiency is increased by more than 3 times. At the same time, the strapping standards are more consistent, the error is small, and the safety is high. For companies that pursue stable beats, controllable quality, and unified packaging standards, it is not only an efficiency tool, but also an important guarantee for brand image output.

Related