Why are more and more companies choosing fully automatic stretch wrapping machines?

Date: 2025-08-21Id:352Views:

Pallet packaging is moving towards automation and intelligence.

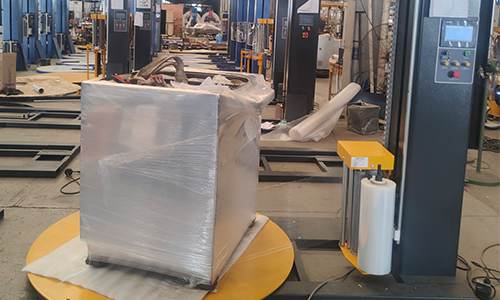

With the development of the warehousing and logistics industry, the speed of palletized cargo removal and the stability of packaging have become critical aspects of business operations. Manual film wrapping is not only inefficient but also suffers from uneven film consumption and loose packaging. Fully automatic stretch wrapping machines, with their high efficiency, stability, and intelligent features, are becoming the mainstream choice across various industries.

Equipment Functions and Core Advantages

Fully automatic stretch wrapping machines utilize a turntable to achieve full-scale wrapping of palletized goods. Their pre-stretching system can stretch the film up to 250%, minimizing material consumption while ensuring secure packaging. The machine offers multiple operating modes, including bottom reinforcement and top corner wrapping, to ensure optimal packaging for different goods. Automatic film loading, cutting, and smoothing functions eliminate manual intervention, saving significant time and labor. Optional features include top covering, top pressing, weighing, and explosion-proofing.

Scope of Application and Industry Applications

Fully automatic stretch wrapping machines are widely used in industries such as food and beverages, chemical raw materials, papermaking, electronics, home appliances, and building materials. Especially useful on production lines with high volumes and demanding cycle times, they ensure secure packaging within a short timeframe, minimizing backlogs and delays. For companies exporting, a neat, standardized appearance and reliable protective performance can also enhance customer recognition of product quality.

Case Study: Application Practice in the Papermaking Industry

During peak season, a paper mill needed to package hundreds of pallets daily, and manual labor was significantly inefficient. After introducing a fully automatic stretch wrapping machine, the packaging time per pallet was reduced to under 45 seconds, improving efficiency by nearly 40%. Furthermore, the pre-stretching function reduced film usage by approximately 18%, effectively reducing packaging costs. Customers reported improved stability and a significant reduction in breakage rates during transportation and storage.

From Savings to Stability: Comprehensively Optimizing the Packaging Process

Fully automatic stretch wrapping machines are more than just a tool for replacing manual labor; they enable standardized, controllable, and energy-efficient packaging processes. Companies using this type of equipment not only reduce labor and consumables costs but also ensure consistent quality for every shipment. For companies transitioning to automation and intelligent manufacturing, fully automatic stretch wrapping machines have become essential for enhancing competitiveness.

Related