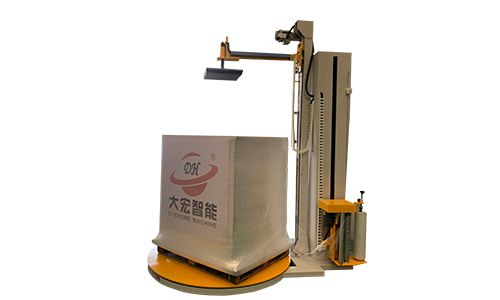

Top Wrapping Machine: An Efficient Solution for Comprehensive Protection of Palletized Cargo

Date: 2025-08-25Id:353Views:

The demand for comprehensive protection in pallet packaging continues to grow.

In the warehousing and logistics industries, pallet packaging not only improves transportation efficiency but also, more importantly, ensures the integrity of cargo during transportation and storage. Traditional wrapping machines provide adequate side protection in most scenarios, but the lack of effective top protection poses a significant challenge for companies dealing with environmental conditions such as rain, dust, and long-distance transport. To address this issue, the all-in-one wrapping machine, combining wrapping and capping, has emerged. It combines wrapping and capping processes, helping companies achieve truly comprehensive packaging protection.

Features: Wrapping and capping in one go

The all-in-one wrapping machine adds a capping mechanism to traditional wrapping machines, allowing it to simultaneously apply a top film layer during the wrapping process, creating a sealed barrier. The machine's built-in pre-stretching system stretches the film by 150%-300%, improving its grip and significantly reducing film material consumption. The intelligent control system allows users to flexibly configure the number of wraps, reinforcement tape position, and capping action through a human-machine interface, ensuring standardized and controllable packaging results.

In addition, it can be integrated with automatic packaging machines and conveyor lines to create an unmanned packaging production line, automating the entire process from palletizing, capping, wrapping, to strapping, significantly improving shipping efficiency. Application Scenario: Moisture-proof, dust-proof, and damage-proof requirements across multiple industries

The top-wrapping and wrapping machine is widely applicable to industries such as food and beverage, chemicals, building materials, papermaking, and home appliances. It performs particularly well in shipping products requiring high moisture and dust-proofing. In the food and beverage industry, this equipment effectively prevents rainwater from penetrating during transportation, potentially affecting product quality. In the building materials industry, top-wrapping protects products like tiles and stone from surface damage caused by dust and moisture. In the chemical and fertilizer industries, sealing the tops of bulk bags significantly reduces moisture during transportation, reducing customer complaints.

Case Study: Packaging Upgrade in the Beverage Industry

In their previous export business, a beverage company used stretch film to secure pallets. Due to the humid container environment during transportation, water seepage often occurred, causing the cartons to soften and, in severe cases, even hindering stacking. Since introducing the top-wrapping and wrapping machine, each pallet is now wrapped in approximately one minute, increasing efficiency by approximately 30%. Crucially, the addition of a top cover provides a waterproof layer on top of the goods, significantly reducing the risk of damage and returns during shipment and significantly improving customer satisfaction.

All-round protection is becoming a packaging trend.

The emergence of a top cover wrapping machine addresses the shortcomings of traditional wrapping packaging in terms of top protection, providing businesses with a more complete packaging solution. It not only improves efficiency and consumables costs, but also creates value in terms of transportation safety and customer experience.

Related