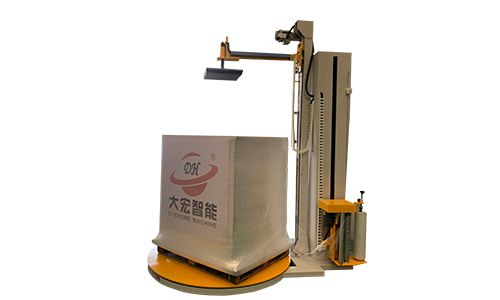

Top Sheet Stretch Wrapping Integrated Machine Stretch Wrapping Equipment for Simultaneous Top and Side Protection of Pallet Loads – Moisture, Dust, and Water Resistance

Date: 2025-12-19Id:466Views:

Limitations of Side-Only Wrapping for Pallet Top Protection

During warehousing and outbound logistics, pallet loads often undergo handling, stacking, and long-term storage. While side-only stretch wrapping can secure the load, the pallet top remains exposed in humid, dusty, or outdoor loading environments. This is particularly relevant for bagged and carton-packed goods, where top protection has become increasingly important. The top sheet stretch wrapping integrated machine is applied to address this requirement by enhancing overall pallet protection.

Coordinated Top Sheet and Wrapping for Five-Sided Coverage

This integrated machine combines top sheet covering and pallet wrapping within a single process. During operation, the top sheet unit first places stretch film over the top of the pallet load. The wrapping system then applies continuous side wrapping, allowing the top sheet and side film to overlap and connect. This coordinated process forms a five-sided protective package without adding manual operations, making it suitable for pallet loads with higher external protection requirements.

Stable Pallet Wrapping Structure Compatible with Standard Packaging Processes

The machine is based on a conventional pallet wrapping structure. The pallet remains stationary while the turntable and film carriage complete the wrapping operation. Wrapping parameters can be adjusted according to pallet height and load weight, allowing different pallet sizes to be processed on the same machine. After the top sheet is applied, side wrapping continues seamlessly, supporting regular packaging cycle times.

Pre-Stretch Film Carriage for Controlled Film Application

The top sheet stretch wrapping integrated machine is typically equipped with a pre-stretch film carriage to maintain consistent film tension during wrapping. By setting appropriate wrap counts and film coverage ranges, the top and side films conform closely to the pallet shape, reducing looseness. This configuration helps maintain consistent packaging quality across different pallet batches and industries.

Standalone Machine Configuration for Flexible Installation

As a single integrated unit, the top sheet stretch wrapping machine can be installed at production line ends or warehouse packaging areas. Pallets can be loaded and unloaded by forklift or manual handling without the need for complex conveyor systems. The clear operation flow makes it suitable for long-term use at fixed packaging stations requiring top protection.

Industry Applications Requiring Enhanced Top Protection

This type of equipment is commonly used in food, beverage, chemical, paper, building materials, and electronics industries. In these applications, combined top and side wrapping helps reduce the impact of environmental factors during transportation and storage while maintaining overall load stability.

A More Complete Protection Solution for Pallet Packaging

As pallet packaging scenarios continue to expand, side-only wrapping is no longer sufficient for all requirements. By combining top and side protection, the top sheet stretch wrapping integrated machine provides a more complete packaging structure and offers a suitable solution for pallet loads that require enhanced top protection in warehousing and logistics operations.

Related