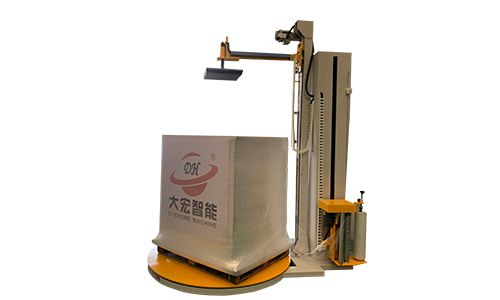

The top wrapping machine helps upgrade the protection of pallet packaging and realizes integrated automatic top wrapping

Date: 2025-06-13Id:247Views:

With the rapid development of warehousing logistics and industrial packaging, enterprises' requirements for cargo packaging are no longer limited to "tight wrapping and high efficiency". More companies are beginning to pay attention to the comprehensive needs of safety protection, dust and moisture resistance, and prevention of stack collapse during transportation. The top wrapping machine was born to solve these pain points. It can not only complete the conventional pallet wrapping operation, but also automatically cover a layer of protective film on the top of the goods, thereby greatly improving the overall closure and transportation stability of the packaging. For industries such as food, chemicals, building materials, e-commerce, and electrical appliances, this is a set of intelligent packaging solutions that integrates protection, beauty, and efficiency.

Precise configuration to meet complex packaging requirements - equipment structure and working principle

The top wrapping machine is mainly composed of a top covering mechanism, a column film rack, a turntable system, and an electronic control system. An automatic film-loading device is set on the top of the equipment, which can accurately cover the PE film on the top of the pallet goods after the goods enter the packaging area, and then cooperate with the turntable and the film rack to complete the overall wrapping. The PLC system is fully controlled, the parameters can be set freely, the top film size is adjustable, the number of winding circles, tension, and speed can be adjusted, and it is suitable for packaging goods of various sizes and materials.

Efficiency and closure are taken into account - functional highlights and technical advantages

Unlike traditional wrapping machines, the top wrapping machine realizes the integrated operation of "top protection + side wrapping". The top film can effectively prevent the intrusion of rain and dust, and is suitable for high-demand scenarios such as open-air stacking and long-distance transportation. Its winding structure adopts a high-tension film pulling system, with high film utilization, strong wrapping force, and the packaging is not easy to loosen. The equipment supports unmanned operation and can be linked with the conveyor line, paper top machine, and baler to form a fully automatic packaging line, which is suitable for enterprises with large-scale shipments.

Case witness, efficiency is intuitively comparable - a food cloud warehouse application example

A large food cloud warehouse enterprise in Shandong, because the original packaging process only does wrapping, the top of the goods is frequently exposed, resulting in moisture, label loss, and a high return rate. After the customer introduced our customized top wrapping machine, the original manual film covering process was cancelled to achieve fully automatic capping + wrapping packaging. On average, 1-2 minutes of packaging time is saved per pallet, 2 people are reduced, daily packaging efficiency is increased by 30%, and the after-sales complaint rate is reduced by about 60%. Users said that after the equipment was put into production, it not only improved the packaging standardization, but also significantly improved the brand image.

A key step to improve packaging quality-application prospects of top wrapping machines

In e-commerce, electrical appliances, building materials and other industries, pallet loading is becoming more and more diversified, and some products are particularly sensitive to top protection, which is difficult for traditional wrapping machines to handle. Through structural integration and intelligent upgrades, the top wrapping machine provides enterprises with a higher specification and higher standard automated packaging method. In the future, with the improvement of warehousing and transportation standards, top wrapping + wrapping will become the new normal for packaging protection, and it is an important step for various enterprises to build an automated and standardized logistics system.

Related