The overall solution of the plate packaging automation production line realizes one-stop packaging and efficient output

Date: 2025-07-14Id:295Views:

In the furniture manufacturing, building materials, glass processing and other industries, plate products must go through multiple packaging processes such as palletizing, film wrapping, and strapping before leaving the factory. However, traditional manual operations generally have the following problems: slow beats, high manpower, unstable quality, and irregular packaging. In the context of increasing order volume and increasing customer requirements, manual methods have become a bottleneck restricting delivery efficiency. More and more companies are beginning to look for a standardized, automated, and efficient packaging system to replace manual operations. The "overall solution for plate packaging automation production line" came into being in this context.

From loading to discharging, one line solves the packaging problem

A complete plate packaging automation production line usually consists of the following core modules:

Automatic stacking-feeding system: The stacked plates are automatically transported to the film wrapping area through rollers or belt conveyor lines, reducing manual handling and improving the feeding rhythm;

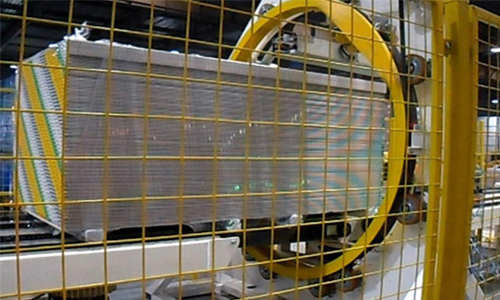

Horizontal film wrapping module: The ring structure is used to wrap the plates for multi-layer protection, and the film tension and number of circles can be preset to achieve edge protection, dust and moisture protection;

Automatic strapping module: After the plates are wrapped, they immediately enter the strapping area. The system can realize 1-3 strapping operations, and the strapping, tightening, hot melting and cutting are automatically completed; some can also be equipped with corner protection devices.

Finished product discharging area: After packaging is completed, the product is automatically output by the conveyor line, and the entire process does not require manual handling.

The entire line realizes full linkage through PLC centralized control + sensor + variable frequency speed regulation system, truly achieving "plate in, finished product out", and realizing the automation and standardization of the packaging process.

The beat rate is increased by more than 2 times, saving manpower, film and time.

The average board packaging time of an automatic packaging production line is only about 2 minutes, which is 2 to 3 times more efficient than manual operation. The entire line only requires 1-2 personnel to monitor and replenish materials, which can replace more than 3 people in traditional packaging positions. The film wrapping module adopts pre-stretching technology, which saves about 30% of film material compared with manual methods; the strapping system accurately controls the dot position and the binding force is consistent to avoid transportation damage caused by human errors. The entire packaging effect is tighter, more beautiful and unified, and the delivery standard is fully upgraded.

Adapt to various specifications of boards to meet the needs of various industries

The board packaging automatic production line supports non-standard customization, and can adjust the module according to the length, width, height, weight, material, etc. of the board. Adapt to:

Furniture industry: solid wood board, multi-layer board, cabinet door board, paint-free board;

Building materials industry: PVC board, gypsum board, insulation board, aluminum-plastic board;

Glass industry: flat glass, mirror glass, electric control glass, etc.;

Plastic/metal industry: honeycomb board, plastic partition, metal guard plate, etc.

The packaging system can also be intelligent, making the shipping process more stable, faster and more labor-saving.

With the expansion of production capacity, the increase in labor costs and the improvement of customer requirements, the packaging process of sheet products must be upgraded to automation. The automated production line for sheet packaging not only helps companies improve the rhythm of shipment, reduce labor input, and control the loss of film materials, but also realizes the traceability of packaging data and the unification of quality standards. It is an effective tool to improve the packaging management level of enterprises. In the future, whoever masters the efficient, stable and low-cost packaging capabilities will take the initiative in market competition. From now on, a packaging production line will solve all problems for you.

Related