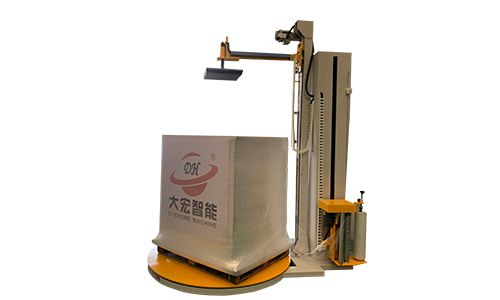

Pallet Top Laminating Machine: A Key Equipment for Improving Palletized Cargo Protection

Date: 2025-09-03Id:367Views:

Higher Requirements for Pallet Transportation Protection

Pallet packaging has become a mainstream form of packaging in modern logistics and warehousing. However, in actual shipping, many companies have discovered that simply wrapping the sides with stretch film is insufficient to fully ensure the stability and safety of goods. This is especially true during outdoor storage or long-distance transportation, where the top of goods is often damaged by rain, dust, or pressure. Therefore, pallet top laminating machines have become an increasingly important supplement to the packaging process. They add a protective top layer to the traditional wrapping process, creating a comprehensive protective effect.

Equipment Features: Automatic Top Covering for More Comprehensive Safety

The pallet top laminating machine automatically laminates the top of goods by working in conjunction with the wrapping machine. Equipped with automatic film loading, cutting, and top covering devices, the machine automatically applies film of a preset size, evenly covering the top of the goods, after wrapping the bottom and sides of the pallet. It then continues wrapping and reinforcing the sides. This process effectively blocks the ingress of rain, dust, and foreign matter, making it particularly suitable for goods stored outdoors or shipped long distances by sea. Furthermore, the machine utilizes a programmable logic controller (PLC) and a human-machine interface, allowing users to freely configure the top cover size and wrapping method to accommodate pallets of varying heights and specifications. It also features a film pre-stretching function, ensuring secure packaging while reducing consumables, achieving the dual goals of secure packaging and cost savings. Its highly automated operation allows for seamless integration into fully automated packaging lines, enabling truly unmanned operation.

Application Industries: Meeting Diverse Protection Needs

Pallet Top Laminating Machines have a wide range of applications, primarily in the food and beverage, chemical, building materials, electronics, and pharmaceutical industries. For example, in the food and beverage industry, products are often stored in humid or dusty environments, and top laminating protects packaging boxes from rainwater penetration. In the chemical industry, bulk bags and drums are protected during transportation by top laminating to prevent dust contamination and leakage. In the building materials industry, palletized cargo, such as boards and tiles, often have flat tops, requiring protective film to protect against compression and contamination during transportation. For export-oriented companies, pallet top laminating can also enhance the overall packaging image, increasing customer recognition of product quality and standardization. Case Study: Upgrading Warehouse Protection for a Food Company

A food processing company often encountered moisture on the top of pallets during product shipment due to limited warehouse storage conditions during the rainy season. This caused the packaging boxes to deform and even damage the contents. The company introduced a pallet top laminating machine, which automatically covered the top of the pallet. The machine, integrated with the existing wrapping machine, formed a complete "wrapping + laminating" packaging process, reducing processing time per pallet to approximately one minute. Since the machine went online, the company's cargo loss rate has decreased by 20%, customer complaints have been significantly reduced, and overall warehouse and transportation safety has been significantly improved.

A Comprehensive Option for Pallet Packaging

The use of a pallet top laminating machine provides companies with a more comprehensive packaging protection method. It not only addresses the top protection limitations of wrapping alone but also makes the packaging process more automated and standardized. With the growing demand for logistics and exports, this type of equipment will become an ideal choice for companies in a growing number of industries to upgrade their packaging systems and enhance cargo safety.

Related