Packaging Problems Solved! How Horizontal Wrapping Machines Earn Corporate Trust

Date: 2025-04-23Id:164Views:

In a large building materials factory, workers once struggled with packaging lengthy steel pipes and panels. Traditional vertical wrapping machines were like a small person trying to carry oversized cargo—utterly inadequate. Not only was packaging efficiency low, but the wrapping was often loose, leading to frequent transport damage and significant losses for the company. The introduction of horizontal wrapping machines completely transformed this situation.

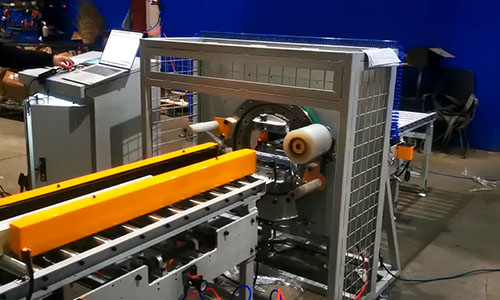

Horizontal wrapping machines adopt a unique horizontal-loading operation mode, distinctly different from traditional vertical wrapping methods. This innovative design is tailor-made for large, irregularly shaped goods. During operation, the goods "lie flat" on the conveyor track while the rotating mechanisms at both ends of the machine work in perfect sync with the film carriage, applying stretch film evenly over the cargo surface in a spiral pattern. It's like dressing the goods in a snug yet sturdy "protective suit," effectively avoiding issues such as toppling or misaligned wrapping caused by unstable weight distribution in vertical wrapping.

Moreover, the operation interface of horizontal wrapping machines is highly user-friendly and intuitive. Even newly hired, inexperienced employees can quickly master it after minimal training. Simply input parameters like cargo dimensions and weight into the control panel, and the machine, like a smart assistant, automatically selects the optimal wrapping solution. It also supports layered wrapping to reinforce critical areas, intelligently adjusts film usage to minimize waste, and seamlessly switches between full-wrap and partial-wrap modes to perfectly adapt to various transport needs. Beyond that, horizontal wrapping machines easily integrate with automated production lines, enabling a seamless "production-packaging-transportation" workflow that significantly boosts overall efficiency.

From a cost perspective, horizontal wrapping machines deliver tangible benefits. Their standardized, automated packaging process dramatically reduces labor costs. Tasks that once required multiple workers can now be handled by a single machine. At the same time, intelligent film usage adjustment cuts material waste, lowering consumable expenses. For businesses, choosing a horizontal wrapping machine means embracing a future of cost reduction and efficiency gains. Whether for construction material producers, logistics firms, or precision equipment manufacturers, horizontal wrapping machines serve as powerful allies in overcoming packaging bottlenecks, injecting new momentum into corporate growth.

Related