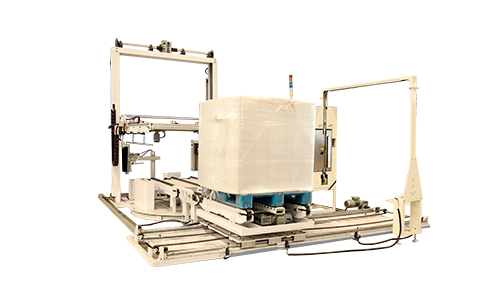

Is it difficult to strap large-size pallets? The sword-piercing pallet strapping machine accurately wears the strap to solve the problem of inadequate packaging

Date: 2025-06-03Id:231Views:

In the manufacturing and logistics transportation industries, the stability of pallet cargo is crucial to transportation safety and warehousing efficiency. Especially in industries such as steel, building materials, chemicals, home appliances, and paper products where whole pallets are shipped frequently, although traditional wrapping packaging can provide basic tightening protection, there is still a certain risk of loosening and loose packaging for heavy, high, and easily displaced goods. For this reason, the sword-piercing strapping machine, as an automated equipment that performs high-strength packaging by "passing through the bottom of the pallet", is increasingly appearing in major factories and logistics storage centers. With its high stability, reliable packaging, and seamless docking with automatic lines, it has become a key equipment for enterprises to improve shipment quality and packaging efficiency.

Equipment principle analysis: How does the sword-piercing strapping system achieve integrated fixation of pallets

The sword-piercing strapping machine is a device designed for the overall packaging of pallet goods. It passes through the bottom of the pallet during the packaging process to form a complete strapping loop. The plastic steel belt or PP belt is inserted from one side of the goods through the sword-piercing path, and is recovered from the other side after passing around the bottom of the pallet, and the packaging is completed by tensioning, hot melting or friction welding.

The advantage of this equipment is that the sword-piercing path bypasses the bottom of the pallet, which can realize the integrated fastening of the goods and the pallet, which not only prevents the goods from sliding, tilting, and falling during movement or transportation, but also improves the stability and seismic resistance of the overall stacking. The whole machine is controlled by PLC program, and the whole process of sword-piercing, tightening, welding and rewinding is completed automatically. It has high packaging efficiency, strong repeatability and less manual participation, which is suitable for high-tempo automatic packaging production lines.

Performance highlights: Five core advantages of sword-piercing strapping machine

1. Firm packaging and improved transportation stability

Traditional wrapping packaging mainly acts on the periphery of the goods and has limited effect on the connection at the bottom of the pallet. The sword-piercing strapping can "hold" from the bottom, which can effectively prevent the displacement and tilt of the goods, and ensure the overall stability of the pallet during high-speed logistics and frequent forklift handling.

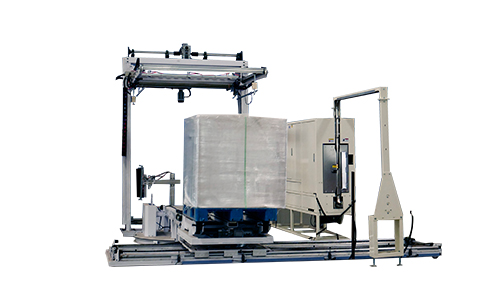

2. Strong compatibility, adaptable to a variety of pallets and cargo types

The equipment supports a variety of specifications of pallets (wooden pallets, plastic pallets, field-shaped pallets) and different sizes of goods. Multiple strapping paths can be set, such as two parallel paths or four well paths, etc., to meet the packaging solution needs of different industries, and are widely used in shipping scenarios in heavy machinery, paper products, building materials and other industries.

3. Automatic control, adaptable to intelligent packaging production line

The whole machine adopts PLC and human-machine interface control system, which can be connected with winding machine, conveyor line, robot collaborative arm and other equipment to realize unattended automatic packaging process. Users can freely set parameters such as strapping times, strapping strength, welding time, etc. to meet the diversified production rhythm.

4. Flexible strapping and saving consumables cost

Supports the use of PET, PP, composite plastic steel strap and other straps, (13.5mm x0.85mm fully automatic PP strapping tape or PET strapping tape (12mmx0.6mm fully automatic PET strapping tape), the thickness of the tape is automatically identified and selected according to the weight of the goods. It has high welding strength and low breakage rate, and its use cost is better than that of metal tape, and it is not easy to rust or scratch the goods.

Successful case:

A large household appliance manufacturing company in Guangdong has frequent product exports, with an average daily pallet shipment of more than 400 pieces. The goods frequently have problems such as loose packages and damage during long-distance sea transportation and port transshipment. In order to improve the overall shipment packaging stability, the company launched a sword-piercing strapping machine and an online winding system to form a fully automatic packaging line. The equipment sets two sword-piercing packaging paths in the horizontal and vertical directions, and is linked with the back-end inkjet system to achieve one-stop finished product packaging and delivery. After 3 months of use, the damage rate of goods has dropped by about 65%, and customer feedback has improved significantly. It is good, and at the same time saves 80% of the packing manpower, saving hundreds of thousands of yuan in annual packaging costs.

The sword strapping machine promotes the upgrading of packaging standards and reshapes the new norms of industrial logistics shipments.

As industrial manufacturing continues to pursue efficiency and standardization, the stable packaging of pallet goods is not only related to transportation safety, but also to brand image and customer satisfaction. As a key packaging equipment, the sword strapping machine is becoming an important promoter of the standardization and automation upgrade of the whole pallet packaging with its structural advantages of "bottom locking goods" and intelligent automation characteristics. In the future, with the continuous optimization of equipment technology and the continuous expansion of industry scenarios, the sword strapping solution will provide more companies with more reliable and efficient logistics packaging solutions.

Related