Horizontal strapping machines help industrial packaging automation, efficient and stable strapping solutions

Date: 2025-06-12Id:246Views:

The importance of horizontal strapping machines, a key tool for upgrading packaging automation

The important role of horizontal strapping machines in modern industrial packaging cannot be ignored. With the continuous upgrading of automated production and logistics systems, traditional manual strapping is not only inefficient, but also has many safety hazards, and packaging quality is difficult to guarantee. As a key equipment for realizing packaging automation, horizontal strapping machines can quickly and stably complete the strapping of goods of various specifications, improve the overall efficiency and safety of the company's packaging line, and become the preferred automated strapping solution for many industries such as manufacturing, logistics, building materials, and e-commerce. This article will focus on the core structure, functional characteristics and practical application cases of horizontal strapping machines to comprehensively analyze their value and advantages in industrial packaging.

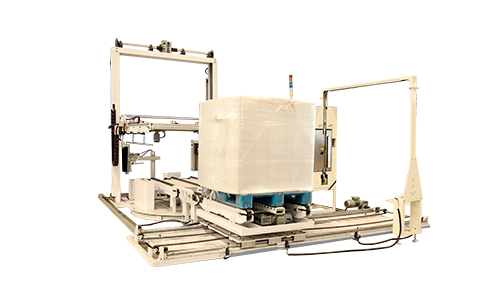

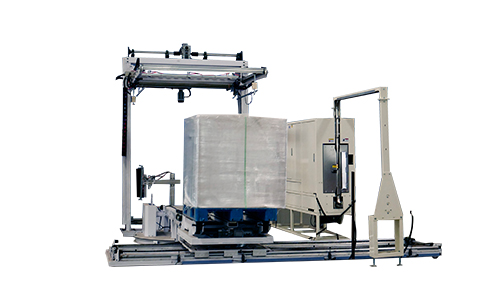

Precise design supports efficient operation - the structure and control system of the horizontal strapping machine

The design core of the horizontal strapping machine is the horizontal wrapping strapping structure. The equipment is generally equipped with a conveying system and an automatic feeding device, which is suitable for pallet cargoes of various sizes. Through the PLC control system and the touch screen operation interface, users can flexibly set multiple strapping and start-up modes to meet different packaging needs. The equipment adopts a high-strength steel structure, which is stable and durable. The mechanical transmission part is equipped with a servo motor to ensure the accuracy and consistency of the strapping process. The strapping belt is automatically fed in by a special feeding mechanism, and is automatically cut and welded after strapping, which reduces manual intervention and greatly improves the operation speed and packaging quality.

Intelligent functions create a safe and efficient packaging experience

In terms of functions, the horizontal strapping machine has a number of intelligent configurations. Its core is the efficient strapping link, which supports the rapid strapping of pallets, boxes or irregular goods to ensure that the goods are stable and not scattered during transportation. The advanced tension control system can automatically adjust the strapping force according to the material and shape of the goods, avoiding damage to the packaging due to over-tightening of the strapping, and preventing the movement of goods due to over-looseness. The equipment is equipped with safety protection measures, emergency stop switch and fault alarm function to ensure the safety of operators. In addition, the horizontal strapping machine can be seamlessly connected with the conveyor line, which is suitable for assembly line operation and further improves the level of packaging automation.

Real cases verify the strength of the equipment-application practice of large building materials enterprises

Take a large building materials manufacturing enterprise as an example. The company's daily output of pallet packaging exceeds 200 pallets. Traditional manual strapping is inefficient and labor-intensive. After the introduction of the horizontal strapping machine, the packaging process is fully automatic, the strapping speed is increased by nearly 3 times, and 5 workers are saved per shift, which greatly reduces labor costs and safety risks. The equipment has excellent stability and almost no fault-free shutdown, ensuring the continuous operation of the production line. According to feedback from the company, the horizontal strapping machine not only improves the beauty and stability of the packaging, but also effectively reduces the damage of goods during transportation, and the overall logistics experience is greatly improved.

Towards a new era of intelligent manufacturing-the future development trend of horizontal strapping machines

As an important part of modern packaging automation, the horizontal strapping machine adapts to the growing demand for efficient and safe packaging in many industries. Through precise mechanical design and intelligent control system, the equipment not only ensures the quality of bundling, but also reduces the labor cost and packaging risk of enterprises. In the future, with the continuous advancement of Industry 4.0 and intelligent manufacturing, horizontal bundling machines will play a greater role in the field of automated packaging, helping enterprises build a more efficient and safe logistics supply chain.

Related