From Moisture Protection to Dust Prevention: How Top Cover Stretch Wrapping Machines Safeguard Cargo?

Date: 2025-04-29Id:176Views:

I. Top Cover Stretch Wrapping Machine: Addressing Pain Points in Pallet Packaging

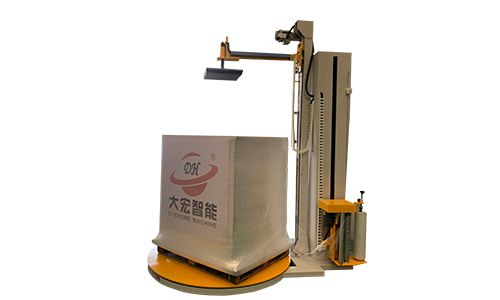

The top cover stretch wrapping machine is an intelligent packaging device built upon traditional pallet wrapping machines, capable of automatically covering the top of cargo. Through automated operation, it not only wraps the sides of the goods but also precisely covers the top, effectively solving moisture and dust prevention issues in container shipping or loose pallet packaging.

Its core advantages include:

Fully Automatic Wrapping: Uses photoelectric sensors to detect cargo height and activates the top cover mechanism accurately without manual intervention.

High Efficiency: Can complete 10-20 pallets per hour, significantly improving logistics efficiency.

Wide Applicability: Suitable for industries such as chemicals, electronics, food, and construction materials, especially for fragile goods like glass and ceramics.

II. Performance Advantages: Why Choose a Top Cover Stretch Wrapping Machine?

Intelligent Control System

Equipped with PLC programmable control for simple operation—just press a button to start the entire packaging process.

Parameters like top/bottom wrapping layers and cycles can be directly set via the control panel, flexibly meeting diverse packaging needs.

High-Efficiency Turntable & Film Frame System

Variable-frequency speed adjustment (0-12 rpm) with automatic reset after completion.

Film frame supports 250% pre-stretching, significantly reducing film consumption and lowering packaging costs.

Independently adjustable lifting speed, paired with wear-resistant rubber rollers, ensures long-term stable operation.

Rich Optional Features

Top Pressing Device: Enhances stability for unevenly stacked goods.

Open-Door Film Frame: Facilitates film threading and replacement, minimizing downtime.

Ramp Design: Eases manual loading/unloading, improving operational convenience.

III. Practical Applications: Meeting Packaging Needs Across Industries

Top cover stretch wrapping machines are widely used in scenarios such as:

Chemical Industry: Moisture-proof packaging to prevent product deterioration.

Food & Beverage: Ensures hygiene and reduces contamination risks during transit.

Electronics & Appliances: Dust protection for safe transportation of precision components.

Building Materials & Ceramics: Secure packaging to minimize breakage rates.

Case Example: A food company improved packaging efficiency by 30%, reduced transport damage by 15%, and saved over $14,000 annually after adopting the machine.

IV. About Dahong Intelligent

Established in 2005, we specialize in R&D and manufacturing of packaging equipment. Certified under ISO9001 and EU CE standards, our products are trusted globally for their cost-effectiveness and reliability. Beyond top cover stretch wrappers, Dahong Intelligent offers a full range of wrapping machines and tailored solutions to support automated packaging upgrades.

Final Notes

With its intelligent and high-efficiency features, the top cover stretch wrapping machine has become a preferred choice for enhancing packaging quality. Whether for moisture/dust protection or cost savings, it delivers practical solutions. For more details, contact Dahong Intelligent for expert consultation.

Related