Application of Pallet Stretch Wrapping Machines with Top Sheet Coverage in Warehouse Protection Packaging

Date: 2026-01-15Id:499Views:

Practical Demand for Full-Coverage Pallet Protection

In warehousing and logistics dispatch processes, palletized goods undergo handling, stacking, and transportation. Conventional side wrapping alone may not effectively protect goods from dust, moisture, or environmental exposure. By adding a top sheet covering function to standard wrapping, pallet stretch wrapping machines provide more comprehensive external protection and are increasingly used in scenarios with higher packaging requirements.

Equipment Structure: Coordinated Side Wrapping and Top Coverage

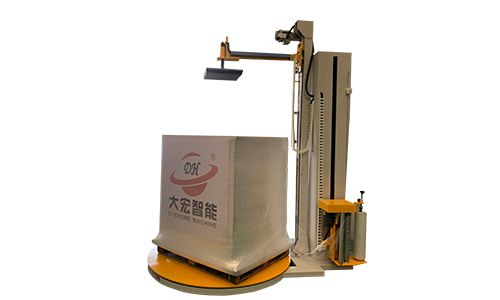

The pallet stretch wrapping machine is based on a rotary turntable structure. Side wrapping is completed through coordinated turntable rotation and film carriage movement. After side wrapping, the top sheet unit applies film over the top of the pallet, connecting seamlessly with the side film layers to create continuous coverage. This structure enhances packaging completeness without altering standard pallet handling methods.

Functional Advantages: Improved Sealing and Load Stability

In practical use, wrapping layers and top coverage positions can be adjusted according to pallet height and load specifications to maintain consistent film adhesion. The top film layer reduces direct exposure to dust and moisture during storage and long-distance transportation. Fully wrapped pallets also present a more uniform shape, facilitating stacking and vehicle loading operations.

Application Scenarios: Warehousing, Outbound Logistics, and Long-Term Storage

Pallet stretch wrapping machines with top coverage are widely used in industries such as food, chemicals, building materials, and daily consumer goods. They are especially suitable for short- to mid-term storage requirements. In outdoor loading, cross-regional transport, or environments with seasonal climate changes, top sheet coverage provides additional protection and helps maintain packaging integrity.

Practical Operation: Standardized Pallet Packaging

In mixed pallet outbound operations, the machine ensures consistent packaging formats across different batches through standardized wrapping and top coverage processes. Stable equipment performance and repeatable parameter settings reduce variability caused by manual operations and support the establishment of clear pallet packaging standards.

A More Complete Wrapping Solution for Palletized Goods

By combining side wrapping with top sheet coverage, pallet stretch wrapping machines provide a more comprehensive packaging solution. In applications requiring dust protection, moisture resistance, and packaging integrity, this equipment offers a practical and repeatable solution for pallet outbound packaging.

Related